BLOW-SCAN Blow Detection System

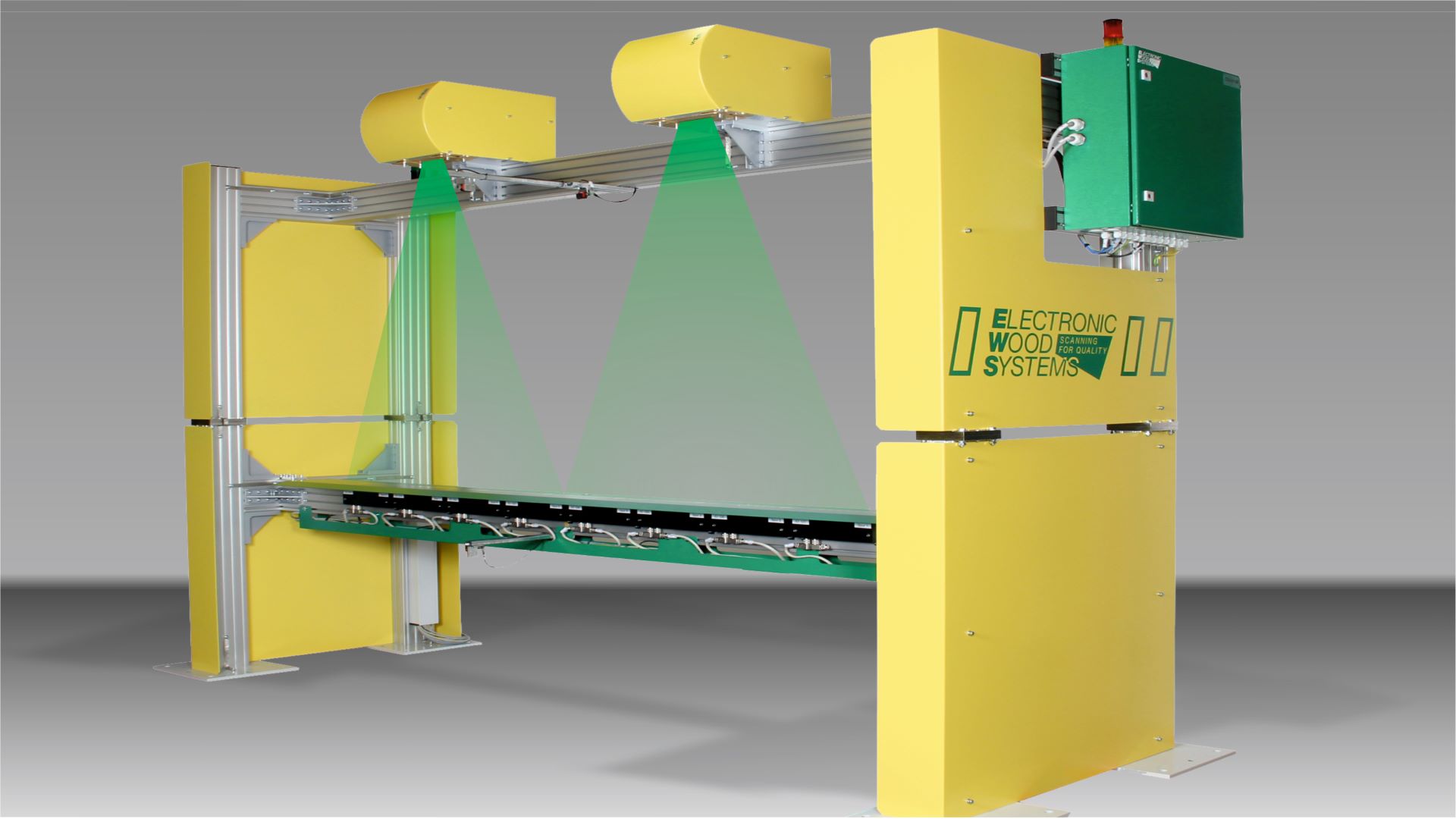

Blow Detection Systems (early warning)

automatically detect blows, bursts and unglued areas during the production of wooden composite panels. They send inaudible ultrasound through the panels and can be deployed in harsh production environments, such as dust, steam and high temperatures.

CONTI SCALE X Non-contact Panel Scale

Continuous Panel Scale uses X-ray technology. Two X-ray tubes are located on a horizontal frame above the panel. The low energy X-ray beams are focused across the production width, but scan the full width of the panel.

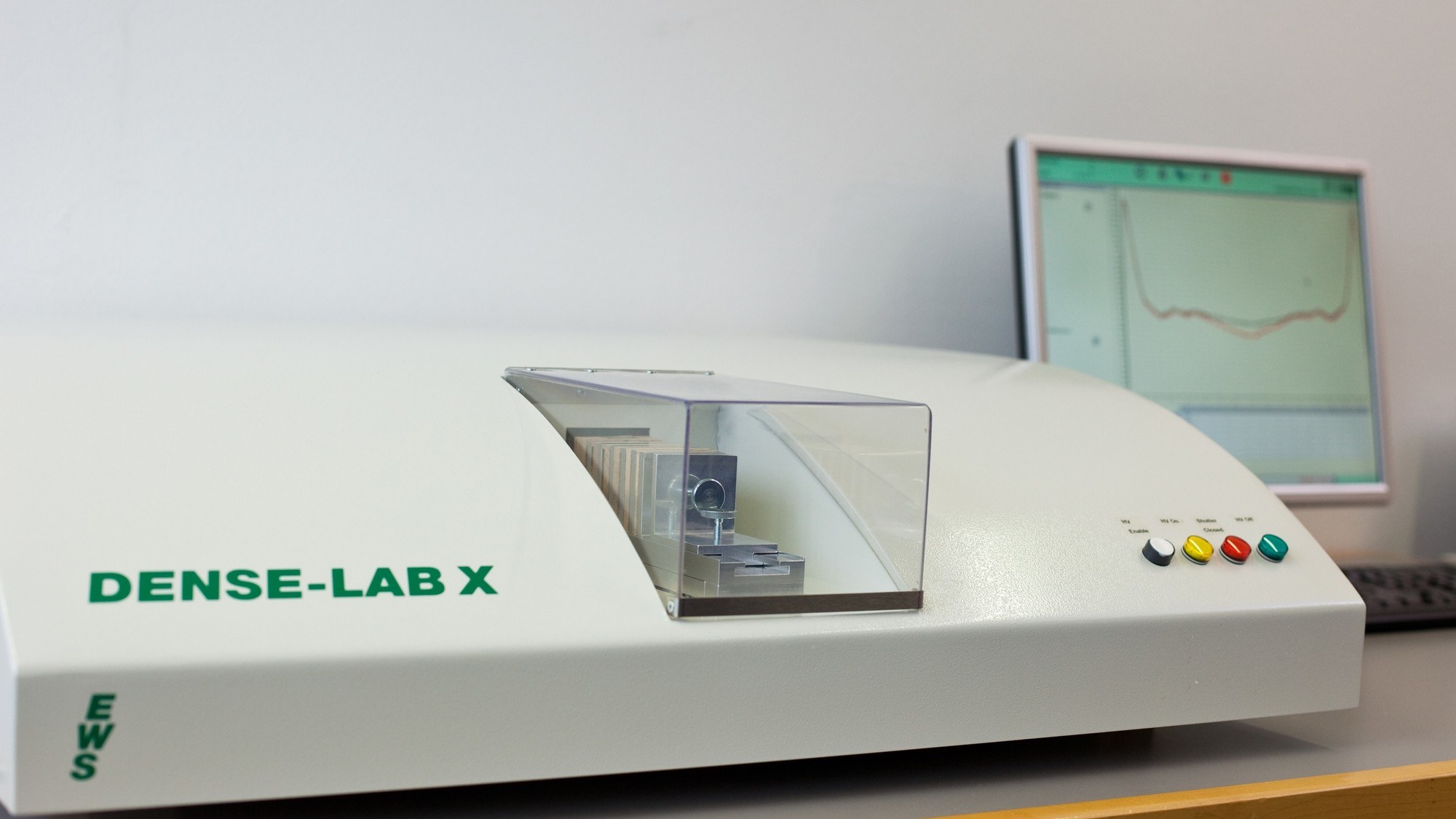

DENSE-LAB X Laboratory Density Profile Analyzer

The laboratory density profile measuring system DENSE-LAB X determines the density distribution over the sample thickness (perpendicular to the panel surface) on small samples with the usual dimension of 50 x 50 mm². The measurement is non-destructive and non-contact using X-ray technology.

EcoScan NEO - FBD (Foreign body detection)

The EcoScan NEO - FBD is able to detect smallest foreign bodies in a fiber mat to prevent damages to the press belts.

EcoScan NEO - FLY (High Resolution Area Weight Gauge)

The EcoScan NEO - FLY measures the material distribution of wood fiber mats.

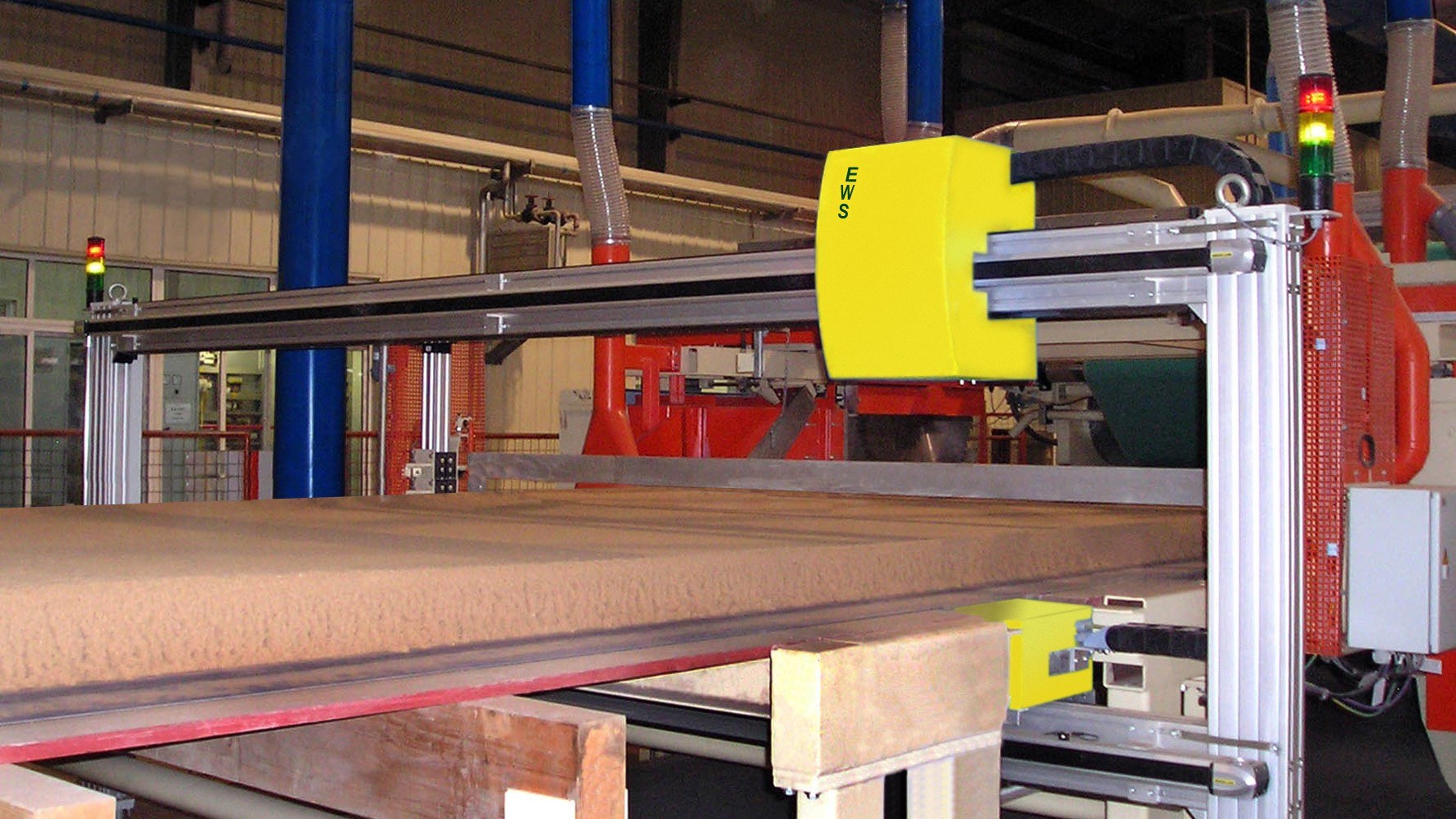

MASS-SCAN X Traversing Area Weight Gauge

One of the most vital factors in the production of wood panels is the constant spreading of material. If tolerances are exceeded, higher material and energy consumption are the consequences. MASS-SCAN X, which constantly moves back and forth across the mat before it enters the hot press, maintains tolerances within the optimum range.

MT-SCAN Infrared Moisture Analyzer

Non-contact measuring of particle and fiber moisture. Multi-wavelength infrared light is used which is targeted to, and reflected by the material surface.

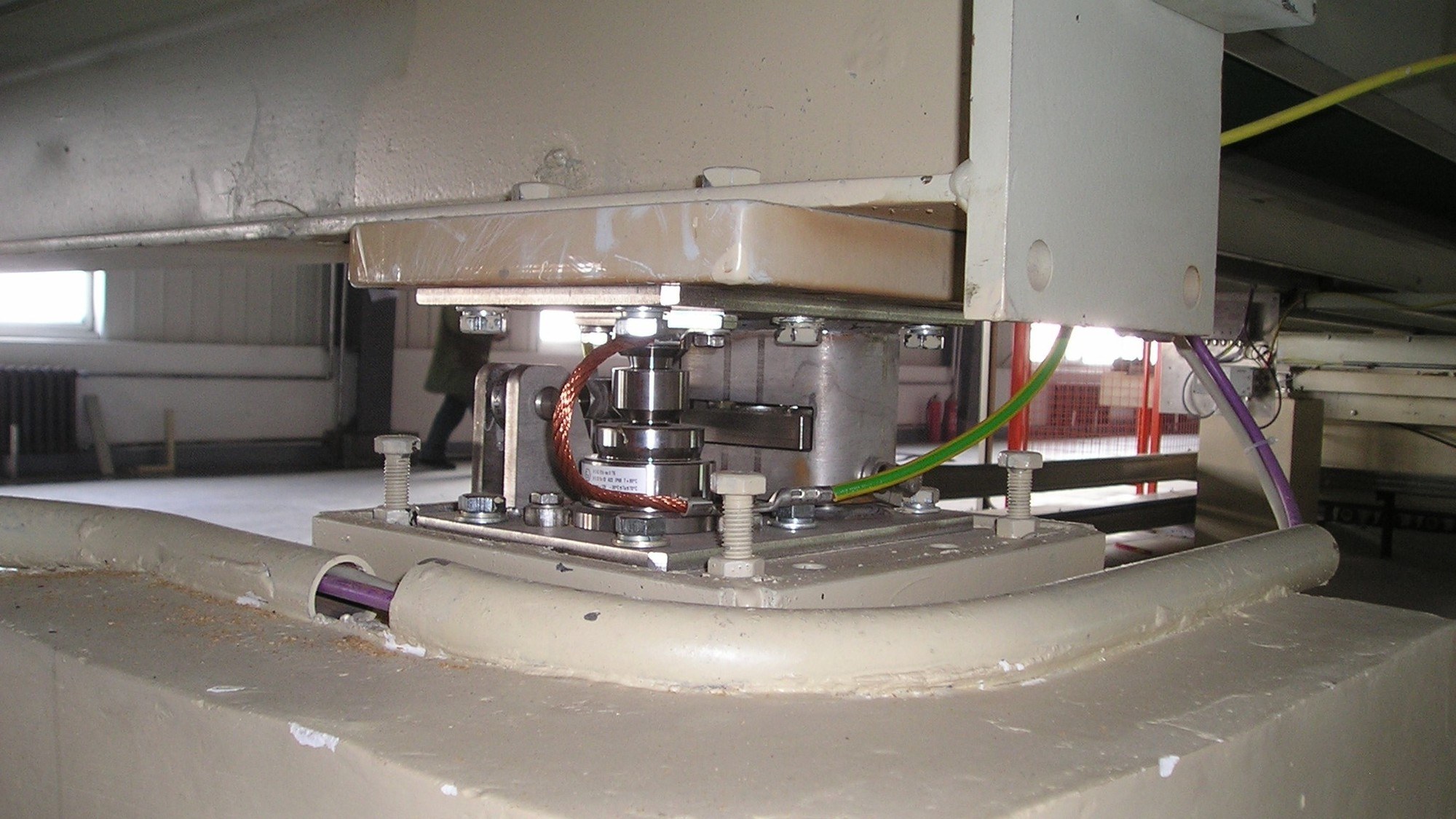

PANEL-SCALE Mechanical Board Scale

Material savings are achieved through accurate panel weight control. Too-high panel weight is result of too-high material input. Too-low panel weight will reduce panel quality.

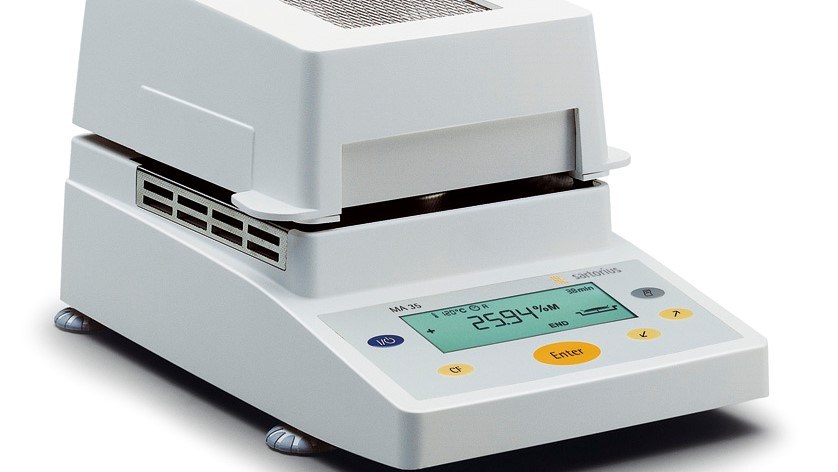

QUICK-LAB Laboratory Moisture Meter

An exact adjusted moisture content of particles or fibers is not only a precondition for producing good quality panels, but also it reduces energy consumption of the drying process, the risk of fire and explosion will be decreased, the blending and pressing process will be optimized.