Continuous Panel Scale CONTI-SCALE X

for LVL, MDF, OSB, OSL, Insulation boards, Particleboards and Plywood

Continuous non-contact Area-Weight Scale

determins the panel weight and its distribution during production by measuring the area-weight and by taking the known panel dimensions into account.

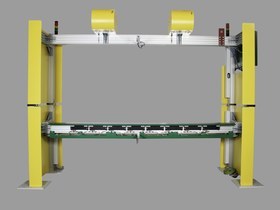

CONTI-SCALE X uses X-ray technology. Two X-ray tubes are located on a horizontal frame above the panel. The low energy X-ray beams are focused across the production width, but scan the full width of the panel. Metal plates on each side of the system prevent someone reaching inside the radiation area.

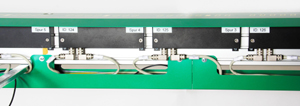

There is no risk to human body parts which might stay beside/outside the system. The X-ray energy will be absorbed. Several detectors are lined up along the lower beam under the panel to measure (per track) the absorbed X-ray energy. This is how the area-weight is measured.

Often the panel weight for evaluation of the density cannot be measured.

For many years finished panels have been weighed by a mechanical weigh scale. The weight most times will be converted to average panel density by adding the thickness values. The weigh scale consists of a belt conveyor located on typically four load cells. These load cells contain bimetals which generate a voltage depending on the force. This force will be converted to display the weight. To avoid dynamic influence on the measurement results the conveying of the panel must be stopped during weighing. This is not always possible, for example, if there is not enough time for stopping the panel. This case requires the panel to be weighed during conveying. This requires a length of the mechanical scale construction of about 1.5 times the maximum panel length. In modern panel production lines these conditions lead to several limitations. Besides space limitations it becomes impossible to accurately weigh short or thin and, therefore, light panels – it simply is not possible. Comparatively it is the same to weigh a ship with and without the captain to find out the captains weight. Example: The weight of a mechanical scale is 2.000kg [4,400lbs]. The accuracy will be about +/- 40kg [88lbs]. A thin panel can have a weight of only 40kg [88lbs]. That means an inaccuracy of 100% (!). This problem provided motivation for EWS to search other methods of weight analysis for panel production. Finally there was the idea to develop the non-contact weigh scale CONTI-SCALE X. The users of CONTI-SCALE X are excited – not only because the little space of 335mm [13.2”] required for installation, not only because of continuous panel weighing, not only because thin, light panels can be measured with high accuracy, but also because the area-weight distribution cross and lengthwise of the panel is shown.

CONTI-SCALE X with 2 X-ray tubes (top) and 8 detectors (below)

Features and Benefits

- Non-contact measurement

- Very little space required, 335mm = [13.2”]

(beneficial in case of press extensions) - High accuracy, especially on thin and light panels

- Automatic calibration in the panel gaps

- Process control to minimum tolerances

- Quality assurance

- Cost reduction of production

- Long life time of X-ray tubes

Visualization

- Panel Weight

- Trend of panel weights

- Area-weight per track

- Total area-weight per panel

- Trend of total area weights

- Panel density

- Trend of total panel densities

- Panel density per track in connection with

thickness measurement system

Installation Location

- After cross-cut saw

- After continuous press

- After multi-opening press

X-ray detectors on lower support beam

Technical Data

Measuring range/precision

Option

- Interface to process control and PLC

Remote maintenance:

"EWS Online Support"

See You Tube: CONTI-SCALE X